Key Signs You Need a Professional PLC Programming Company

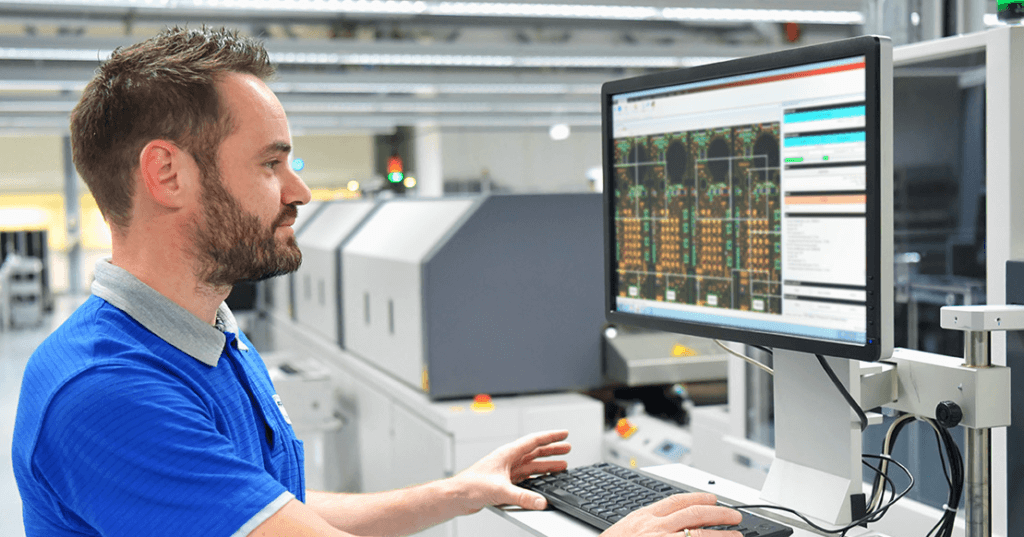

Production floors run on precision. When machines start acting unpredictably, it’s rarely just wear and tear—it’s often hidden programming issues in the PLC system. Knowing when to call in an experienced PLC programming company can save thousands in downtime, protect safety, and keep operations moving without unnecessary headaches.

Recurring Unplanned Shutdowns Despite Manual Restarts

Unplanned shutdowns can be a symptom of deeper problems in the PLC logic. If operators are constantly restarting machines only for them to trip again, the issue often lies in the sequence programming or fault-handling routines. A professional PLC programming company can trace the source of the shutdowns, whether it’s an overlooked interlock, improper fault reset sequence, or outdated ladder logic that can’t handle newer equipment demands.

In high-volume operations, these shutdowns don’t just stop machines—they disrupt schedules, cause material waste, and frustrate staff. By working with specialists familiar with custom PLC systems, including Rockwell Allen Bradley PLC setups, companies can identify faulty logic paths, apply robust fault recovery, and implement long-term stability in the program. This ensures the machines run as intended without operators fighting recurring stoppages.

Frequent Logic Errors Disrupting Production Sequences

Production sequences rely on PLCs to execute every step in the right order. Logic errors—such as skipped outputs, incorrect sensor readings, or timing mismatches—can throw the entire sequence off. This often points to incomplete testing during program updates or changes made without considering downstream effects. A skilled PLC programming company can simulate and test sequences, catching these issues before they reach production.

For facilities asking what is PLC programming really capable of, the answer is this: precise control of complex processes when the logic is written and maintained correctly. Professionals ensure that every rung, function block, or structured text line is optimized for both current production needs and future adjustments, reducing the risk of repeated production faults.

Outdated or Undocumented Program Versions Lacking Change Control

Running a PLC with an outdated or undocumented program version is like using a map without street names—it’s inefficient and risky. Without proper version control, even small changes can introduce new problems, and troubleshooting becomes far slower. Skilled programmers keep detailed records of revisions, backup copies, and change histories, so future updates are done with confidence.

This is especially critical in plants that run multiple PLC types or custom PLC configurations. Whether it’s a Rockwell Allen Bradley PLC or another brand, professionals ensure every line of code is accounted for, the latest tested version is in use, and rollback options are available if a change fails. That level of control prevents confusion and avoids unexpected downtime.

Inconsistent Response Times in Safety- or Mission-critical Processes

In safety-critical environments, milliseconds matter. A PLC that delays triggering an emergency stop or a safety interlock can put people and equipment at risk. Inconsistent response times often result from poorly optimized scan cycles, inefficient programming structures, or hardware overloads. A trained PLC programming company knows how to fine-tune execution order and eliminate unnecessary code to achieve consistent, fast responses.

Industries working with mission-critical processes can’t afford unpredictability. Proper PLC programming ensures that safety conditions override all other logic instantly, whether the system is handling material presses, robotic cells, or hazardous chemical processing. Professional intervention guarantees the PLC reacts exactly when it’s supposed to—every time.

Difficulty Integrating PLCs with Newer Control or SCADA Systems

As plants upgrade to modern SCADA systems or advanced HMIs, older PLC programs often struggle to communicate effectively. Integration challenges may include mismatched protocols, unsupported data formats, or outdated firmware. Skilled PLC programmers can bridge these gaps by rewriting logic for compatibility, updating communication modules, and ensuring seamless data exchange.

For facilities expanding automation capabilities, professional integration ensures that operators can monitor and control all systems from a single platform. Whether it’s retrofitting a legacy Rockwell Allen Bradley PLC or programming a brand-new custom PLC for SCADA compatibility, a programming company ensures smooth interaction between old and new technologies.

Spikes in Maintenance Costs Linked to Unresolved Programming Issues

Maintenance teams often end up spending time and money addressing mechanical symptoms caused by underlying software issues. If adjustments to sensors, actuators, or mechanical systems never seem to resolve recurring faults, the true cause may be hidden in the PLC logic. Programming inefficiencies can cause components to run harder than necessary, leading to premature wear.

By engaging a PLC programming company, businesses can reduce these costs significantly. Professionals pinpoint inefficiencies, refine logic to extend equipment life, and eliminate repetitive troubleshooting steps for maintenance crews. The result is a leaner, more reliable operation where hardware and software work in sync.

Escalating Security Gaps Due to Weak Access Controls or Logic Vulnerabilities

Security isn’t just about keeping people out of the building—it’s about protecting the control system itself. Weak access controls in PLC programming can allow unauthorized changes, while outdated security protocols leave the system vulnerable to cyber threats. Professionals lock down programming access with tiered permissions, password protection, and secure remote connection methods.

In industries where uptime and safety are non-negotiable, addressing logic vulnerabilities is essential. Skilled programmers audit the code for backdoors, unused functions, and insecure connections. Whether the system runs on a Rockwell Allen Bradley PLC or another platform, securing it ensures both operational stability and protection from external risks.